Corrosion Protection for Electronics

.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:1240,h:620,cg:true)

Cortec® VpCI® Offers Complete Full-Service Line Of Products

Cortec® VpCI® products are an excellent quality assurance tool for everything from major manufacturers of electronics to do-it-yourself home-built kits. Corrosion can be stopped at any step from manufacturing to final installation. Integrate all your electronic/electrical protection needs from a single source supplier. Corrosion of complex electrical and electronic equipment is an increasingly serious problem causing expensive failures. Corrosion occurs during manufacturing, shipping, storage, and field operations. It can be caused by Salt, moisture, contaminants, hydrogen sulfide, sulfur dioxide, ammonia, or acid rain, Galvanically-induced attack or Equipment operation in non-controlled atmospheres. With Cortec® Emitting Systems, sensitive equipment is protected against corrosion, thereby extending its life and reducing the cost of expensive repairs.

Cortec® Emitting Systems = Reliability, Service Life, and Cost Reduction.

VpCI ®-101 - Small foam patented device from which VpCI's are slowly released. Protection: 1.0 ft3 (Consumer-91016)

VpCI ®-105- Plastic emitter with breathable membrane. Protection: 5.0 ft3

VpCI ®-111 - Plastic Emitter with breathable membrane. Protection: 11.0 ft3 (Consumer 91112)

VpCI®-130 Series Impregnated Foams Patented Multi-functional VpCI® (Consumer -91321)

Corrosorber® - Absorbs hydrogen sulfide and other corrosive gases.

Corrosorber® Pouch - Uniquely designed pouch containing indicating powder that absorbs corrosive sulfurous gases

Desicorr® - Specially designed pouch to protect products from moisture damage

Desicorr® VpCI® Pouches - Specially designed 2 sided pouch contains a unique combination of desiccant and VpCI®

ElectriCorr VpCI®-238 - Multifunctional multimetal corrosion protection and cleaning indoor use (Consumer 92381)

ElectriCorr VpCI®-239 - Outdoor version of VpCI-238

Contact Us for industrial sales and other inquires

Cortec Emitters and Foams

VpCI®-101 Devices

VpCI®-105 Devices

VpCI®-105 Devices

Product Description

Cortec® impregnated foams and emitters protect precision machined parts and highly sensitive electronic components. They protect against breakage, surface damage, or scratches. VpCI®-101 devices are designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or tool boxes. A VpCI®-101 device protects up to 1 cubic foot (28 liters) in volume. VpCI®-101 is a small patented device from which Vapor phase Corrosion Inhibitors are slowly released. The corrosion inhibitors emit vapors that form a molecular layer on metal surfaces to protect critical, complex, and expensive electronic equipment and other metal components during operations, shipping, or storage. VpCI®-101 provides longterm protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others.

Advantages

• Economical to use • Quick and easy installation, compact and space-saving • Provides continuous protection up to 24 months during operation and/or shutdown • Effective in polluted and humid environments • Does not interfere with electrical, optical, or mechanical performance • Multimetal protection • Non-toxic and safe to handle • Free of nitrites, silicones, and phosphates • No spraying, wiping, or dipping required • Self-stick back, Self-stick date label

Typical Applications

• Operating, packaged, and stored electrical equipment • Marine navigation and communication equipment • Aerospace electrical controls • Electric motors • Switching equipment • Fuse boxes and power boxes • Medical equipment • Electrical wireways and terminal boxes • Control panels for manufacturing and processing equipment • Scientific and measuring instruments • Hand-held battery-operated devices • Telecommunications equipment and remote electronic devices • Tool boxes, parts storage, and other containers holding metals

How to Use

VpCI®-101 devices are extremely simple and convenient to install. The devices should be installed at the earliest possible time, preferably during manufacturing or assembly. Simply select a space within any enclosure where corrosion protection would be useful. Verify the surface where the device will be affixed is clean and free of debris. Peel off the protective peel strip from the bottom of the device and attach it to the clean surface. VpCI®-101 devices can be installed in any position. For volumes greater than 1 cubic foot (28 liters) use more than one device or VpCI-105 or VpCI-111. If the enclosure is not totally airtight, or if the access doors are opened frequently, replace the VpCI®-101 device more often than every 2 years. For additional protection, spray the enclosure very lightly with Cortec® ElectriCorr® VpCI®- 238 or VpCI®-239.

Protection: 1.0 ft3 (.03 m3).

Package: 50/carton.

Contact Us for other sizes and ordering.

VpCI®-105 Devices

VpCI®-105 Devices

VpCI®-105 Devices

Product description

Cortec® VpCI®-105 emitters are unique devices designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or tool boxes up to 5 cubic feet (141.6liters). The VpCI®-105 device emits Vapor phase Corrosion Inhibitors, which form a protective coating on all metal surfaces. VpCI®-105 is a patented plastic 2.3" diameter x 0.75" H emitter with a breathable Tyvek®* membrane through which the corrosion inhibitor is released. It provides long-term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others. Cortec® impregnated emitters protect precision machined parts and highly sensitive electronic components and protect against breakage, surface damage, or scratches. * Tyvek® is a registered trademark of Dupont®

Advantages

• Economical to use • Provides continuous protection for up to 24 months • Effective in polluted and humid environments • Does not interfere with electrical, optical, or mechanical surface properties • Multimetal protection • Quick and easy installation, safe to handle • Protects during operation and shutdown• Compact, space-saving, and unobtrusive device • Free of nitrites, halogens, and phosphates • No spraying, wiping, or dipping required • Self-stick back with self-stick date label • Accepted by FDA for corrosion protection of electrical and electronic equipment within food processing plants • Approved for U.S. military

Typical Applications

• Operating, packaged and stored electrical equipment • Marine navigation and communication electronic equipment • Aerospace electrical controls • Electric motors • Switching equipment • Fuse boxes and power boxes • Medical equipment • Electrical wireways and terminal boxes • Scientific and measuring instruments • Telecommunications equipment • Remote electronics devices • Hand-held battery-operated devices • Control panels for manufacturing and processing equipment • Tool-boxes, gun safes, and enclosure for metal storage

How to Use

VpCI®-105 is extremely simple and convenient to install. The device should be installed at the earliest possible time. Simply select a space within any enclosure where corrosion protection would be useful. Verify the surface the device will be affixed to is clean and free of debris. Peel off the protective peel strip from the bottom of the device and attach it to the clean surface. VpCI®-105 emitters can be installed in any position. For volumes greater than 5 cubic feet (141.6 liters), use more than one device. If the enclosure is not totally airtight, or if the access doors are opened frequently, replace the VpCI®-105 device more often than every 2 years. After periods of heavy maintenance, replace the device.

For additional protection, spray the enclosure very lightly with ElectriCorr® VpCI®-238 or VpCI®-239.

Protection:5.0 ft3 (.14 m3).

Package:20/carton.

Contact Us for other sizes and ordering.

VpCI®-111 Devices

91321 Consumer Version of VpCI®-130 Series

91321 Consumer Version of VpCI®-130 Series

Product description

VpCI®-111 emitters are unique devices designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets or tool boxes up to 11 cubic feet (312 liters). Cortec® emitters protect precision machined parts and highly sensitive electronic components. They protect against breakage, surface damage, or scratches. The Vapor phase Corrosion Inhibitor (VpCI®) emits vapors, which form a molecular layer on internal metal surfaces to protect critical, complex, and expensive electronic equipment during operation, shipping, or storage.

Cortec VpCI®-111 is patented plastic 2.3" diameter x 1.27" H emitter with breathable Tyvek® membrane cover through which corrosion inhibitors are slowly released. VpCI®-111 provides long term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others. *Tyvek is a registered trademark of DuPontTM

Advantages

• Economical to use • Provides continuous protection for up to 24 months during operation and/or shutdown • Effective in polluted and humid environments • Does not interfere with electrical, optical, or mechanical performance • Multimetal protection • Quick and easy installation, compact and space-saving • Non-toxic and safe to handle • Free of nitrites, halogens, and phosphates • No spraying, wiping, or dipping required • Self-stick back and self-stick date label • Accepted by FDA for corrosion protection of electrical and electronic equipment within food processing plants •Approved for U.S. military, NATO and IBM

Typical Applications

• Operating, packaged, and stored electrical equipment • Marine navigation and communication equipment • Electric motors • Switching equipment • Fuse boxes and power boxes • Medical equipment • Electrical wireways and terminal boxes • Scientific and measuring instruments • Aerospace electrical controls • Telecommunications equipment and remote electronics devices • Control panels for manufacturing and processing equipment • Tool-boxes, gun safes, and any other enclosure for metal storage

How to Use

VpCI®-111 is extremely simple and convenient to install and should be installed as early as possible, preferably during manufacturing or assembly. Simply select a space within enclosed device where corrosion protection would be useful. Verify that the surface on which the device will be installed is clean and free of debris. Peel off the protective peel strip from the bottom of the device and attach it to the clean surface. The peel strip can be separated to reveal a self-adhesive sticker on which the installation and replacement dates can be noted. VpCI®-111 emitters can be installed in any position. For volumes greater than 11ft3 (312 L), install more than one VpCI®-111. If the enclosure is not totally air-tight or if the access doors are opened frequently, replace the VpCI®-111 emitter more often than every two years. After periods of heavy maintenance, replace the emitter.

For additional protection, spray the enclosure very lightly with ElectriCorr® VpCI®-238 or VpCI®-239.

Protection:11.0 ft3 (.31 m3).

Package:10/carton.

Contact Us for other sizes and ordering.

91321 Consumer Version of VpCI®-130 Series

91321 Consumer Version of VpCI®-130 Series

91321 Consumer Version of VpCI®-130 Series

Product Description

Bullfrog Rust Blocker Shield (91321)- Stick it up in a Second...Stop Rust for a Year! Cortec® impregnated foams protect precision machined parts and highly sensitive electronic components. They protect against breakage, surface damage, or scratches. Stop rust for a year in any enclosed space up to 50 cubic feet with the invisible molecular protection of VpCI’s (Vapor Phase Corrosion Inhibitors). Ideal for any metal stored in an enclosed area. Used by the worlds largest companies to protect their critical assets from rust and corrosion.

Advantages

• Works better than conventional rust inhibitors, yet is Environmentally and User Safe • No nitrates, silicones, phosphates, heavy metals or other harmful chemicals • Won’t harm plastics, elastomers or painted surfaces • Works even under extreme conditions • Each shield will protect up to 50 cubic feet of space for 1 year

Typical Applications

• Storage lockers • Gun Safes • Large tool chests • Boat storage holds • Truck storage boxes • Pianos • Electrical Cabinets • Any thousands of other uses

How to Use

Simply remove foam 10-5/8" x 10-5/8"x 3/8" shield from plastic bag insert, put back into cardboard sleeve, write the date on back of box and insert into any enclosed space where there is metal for 1 year of corrosion protection. The VpCIs migrate from the foam to all metal surfaces within the enclosed space sealing out air and moisture that causes rust and corrosion.(Larger areas can be protected by combining multiple shields)

Protection: Each shield will protect up to 50 cubic feet

Package:12/carton.

Product Description

Cortec® VpCI®-130 Series Foams are unique flexible packaging materials that combine VpCI® protection, and desiccant action; plus excellent antistatic capabilities all in one step! You can now eliminate expensive and messy rust preventatives with VpCI®-130 Series Foams. Parts protected are always ready for use; no degreasing or coating removal is required. Application of multifunctional materials such as VpCI®-130 Series Foams results in significant weight and labor savings.

Metal parts packaged with VpCI®-130 Series Foams receive continuous protection against humidity, condensation, aggressive industrial atmospheres, dissimilar metal corrosion (galvanic corrosion), salt air, and residual impurities left after processing.

Advantages

Cortec® VpCI®-130 Series Foams are specially designed with Vapor phase Corrosion Inhibitor (VpCI®) impregnated throughout the foam’s polymeric matrix. They are excellent for protection of ferrous, non-ferrous metals, and alloys such as: steel, copper, brass, aluminum, zinc, solder, silver, etc. VpCI®-130 Series Foams do not change critical physical and/or chemical properties of electronic components, and are suitable for protection of printed circuit boards. VpCI®-130 Series Foams are nitrite- and chromate-free. The high performance patented formulation of VpCI® provides fast, easy-to-use protection even in aggressive overseas shipments. VpCI®-130 Series Foams contain approximately ten (10) times more VpCI® chemical per square foot (square meter) of substrate than the traditional VCI papers and other wrapping materials.

Contact Us for other sizes and ordering.

Cortec Corrosober® and Desicorr®

Corrosober® Plastic Cup with breathable membrane

Corrosober® Plastic Cup with breathable membrane

Corrosober® Plastic Cup with breathable membrane

Product Description

Corrosorber absorbs hydrogen sulfide and other corrosive gases. Corrosorber will not interfere with VpCI protection, but instead it will absorb the gases that cause corrosion. Severe damage or failures occur due to the presence of these corrosive species. Corrosorber absorbs hydrogen sulfide and volatile mercaptans, removing them from the atmosphere and eliminating the cause of some damage to metals. The chemicals contained in Corrosorber Plastic Cup with breathable membrane 2.3" diameter x 1.27" H have been especially treated to change color from off-white to black as corrosive gases are trapped. In addition, unlike other products on the market, Corrosorber will not release the corrosive gases back into the atmosphere. The reaction is irreversible, eliminating any concern about post contamination. Corrosorber is non-toxic and has no effect on the environment. It can be handled without safety equipment.

Advantages

Scavenges corrosive gases • Non-toxic, safe to handle • Changes color as it is used up • Irreversible reaction, no post-contamination • Economical, quick and easy installation and very convenient to use • Does not interfere with electrical, optical, or mechanical surface performance • Protects during operation and shutdown • Compact, space-saving, unobtrusive

Typical Applications

• Water treatment plants • Petrochemical plants • Plants handling sulfurous crude oil • Natural gas handling• Pulp and paper plants • Animal agriculture facilities • Operating, packaged, and stored electrical equipment • Marine navigation and communication equipment • Aerospace electrical controls • Electric motors, switching equipment • Fuse boxes, power boxes • Medical equipment • Electrical wireways, terminal boxes • Scientific and measuring instruments

• Telecommunications equipment • Remote electronics devices

How to Use

Install the Corrosorber at the earliest possible time, before shipping or receiving if possible. Simply select a space within any enclosed device where corrosion protection would be useful, and attach with adhesive backing. Replace cup as soon as the container appears gray.

Protection: Up to two years under typical conditions or until color changes from off-white to black.

Package:10/carton.

Contact Us for ordering.

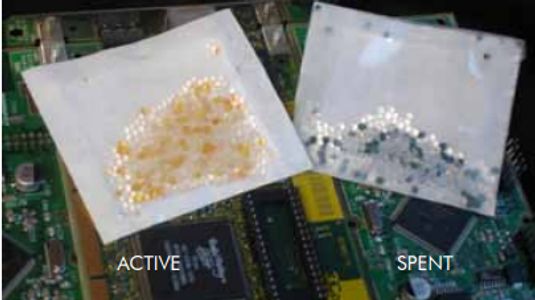

Corrosober® Pouch Hydrogen Sulfide Scavenger

Corrosober® Plastic Cup with breathable membrane

Corrosober® Plastic Cup with breathable membrane

Product Description

Corrosorber® Pouch is a uniquely designed pouch containing an indicating powder that absorbs corrosive sulfurous gases such as hydrogen sulfide and volatile mercaptans. As the Corrosorber Pouch absorbs these corrosive gases the powder will change from green to black notifying the user when it’s time to replace the pouch. Unlike other products on the market, Corrosorber Pouch will not release the corrosive gases back into the atmosphere. The reaction is irreversible, eliminating any concern about post contamination.

Metals are readily attacked by gases such as hydrogen sulfide, mercaptans, and other sulfur compounds that can cause severe damage or failures to occur. The Corrosorber Pouch is a great complement to Vapor phase Corrosion Inhibitors (VpCI®) as it absorbs these gases eliminating a source of corrosion and allowing VpCIs to function more efficiently. Corrosorber Pouches are constructed from breathable Tyvek®* on one side and clear PET film on the other; allowing indication of needed product replacement. * Tyvek® is a registered trademark of Dupont

Advantages • Scavenges corrosive gases • Non-toxic, safe to handle • Changes color as it is used up • Irreversible reaction, no post-contamination • Economical to use • Very convenient to use • Does not interfere with electrical, optical, or mechanical surface performance • Quick and easy installation • Protects during operation and shutdown

Typical Applications

• Petrochemical plants • Water treatment plants • Animal agriculture facilities • Operating, packaged, and stored electrical equipment • Marine navigation and communication equipment • Aerospace electrical controls • Electric motors, switching equipment • Fuse boxes, power boxes • Medical equipment • Electrical wireways, terminal boxes • Scientific and measuring instruments • Telecommunications equipment • Remote electronic devices

How to Use

Install the Corrosorber Pouch at the earliest possible time; before shipping or receiving whenever possible. Simply select a space within any enclosed device where H2S gas is present. Replace pouch when completely changed from green to black.

Protection: Up to two years under mildly sulfurous conditions or until color changes from green to black in more aggressive environments.

Package: Corrosorber Pouches packaged 300/carton.

Contact Us for ordering.

Desicorr® VpCI® Pouches

Product Description

Desicorr® VpCI® Pouch is a specially designed two sided pouch which contains a unique combination of desiccant and VpCI® (Vapor phase Corrosion Inhibitor). Desicorr® VpCI® pouches are ideal for protecting packaged ferrous and non-ferrous metals from corrosion. Unlike conventional desiccants, the dual function of the Desicorr® VpCI® pouches reduces moisture in the air (desiccant action) and provides multimetal protection (VpCI® action) within a package. In essence, the desiccant action allows the VpCI® to have free access to the surface of the metal, without competition from moisture on the metal surface.

Advantages

• Available in 1/6 and 1 Unit sizes • Synergistic action between desiccant and VpCI® gives unparalleled corrosion protection • VpCI continues to provide corrosion protection even when desiccant is fully spent • Color change from yellow to green, allows user to know when desiccant is fully spent • VpCI®action protects recessed and inaccessible surfaces • Protective VpCI® film does not need removal prior to using part • No degreasing or cleaning of protected part required

Multimetal protection • Aluminum • Carbon Steel • Stainless Steel • Copper • Brass • Galvanized Steel • Silicon Steel • Silver • Solder

Typical Applications

Desicorr® VpCI® is designed to protect products, components or assemblies when packaged in corrugated boxes, plastic wrap or bags, and wood or metal containers. •Motors •Completed assemblies, parts and components •Mechanical controls •Precision machined or stamped parts •Tools Marine and commercial electronic equipment • Electrical equipment

How to Use

Manually or automatically insert a Desicorr® VpCI® Pouch into the package. Then immediately close or seal container.

Protection: One Desicorr® VpCI® pouch is designed to protect 1 cubic foot. Desicorr® VpCI® Pouches will protect up to two years. Contains silica gel desiccant spheres and polyethylene VpCI® spheres.

Package: Desicorr® VpCI® Pouches 300/carton.

Contact us for ordering or further information

Desicorr® Pouches

Product Description

Desicorr® Pouches is a specially designed pouch to protect products from moisture damage. Whether in storage or in transit, products in nearly every industry require protection from moisture. Mildew, mold, rust, and an overall decrease in product efficacy are all common effects of moisture, costing millions in returned or unusable products each year. Desicorr® pouches help prevent damage by absorbing moisture.

Dessicorr® Pouches are available in both windowed and non-windowed versions (NW). The windowed version contains some indicator spheres that will change color from yellow to green when the desiccant is fully spent.

Advantages

Dessicorr®Pouches are available in 1/6, 1, and 2 Unit sizes. Dessicorr® pouches are constructed with breathable Dupont Tyvek on one side and clear film on the other, which allows visual confirmation when the desiccant is spent. Dessicorr® contains a desiccant with a color changing indicator: A yellow indicator that turns to green. This allows the user to know when the desiccant is spent and product should be replaced.

Typical Applications

Desicorr® Pouches are designed to protect goods within a sealed moisture barrier package or container from moisture damage. • Semiconductors • Electronics components • Circuit boards • Relays, communication devices • Museum storage • Optical devices • Military instruments • Machine parts

How to Use

Manually or automatically insert a Desicorr® pouch in the package. This number may vary depending on shipping conditions and the nature of the products being protected.

Protection: Desicorr pouches available in 1/6, 1, 2 Unit

Package: Desicorr® Pouches 300/carton. The shelf life of unopened cartons of Desicorr Pouches is up to 24 months. Desiccant spheres can be reused if heated until the yellow color reappears.

Contact Us for ordering.

CORTEC ELECTRONIC SPRAYS

Electricorr® VpCI®-239

Electricorr® VpCI®-238

Electricorr® VpCI®-238

Product Description

ElectriCorr® VpCI®-239 is a multifunctional outdoor cleaner/corrosion protector. Its continuous Vapor phase Corrosion Inhibitor action saves money by extending product life and eliminating downtime due to corrosion. ElectriCorr® VpCI®-239 forms a very thin film proven effective against aggressive conditions including industrial, marine, and tropical regions. This film does not alter the electrical resistance or magnetic properties of metal substrates. ElectriCorr® VpCI®-239 can be safely applied for the corrosion protection of electronic circuits or relays without causing any significant changes in conductivity and can be safely used with most plastics, elastomers, and other non-metallics. In addition to corrosion protection VpCI®-239 is an excellent contact cleaner of oils, grime, and other contaminants and is an effective outdoor inhibitor of galvanic corrosion for most metals and alloys normally found in electrical and electronic applications such as aluminum, copper, tin, and ferrous metals. ElectriCorr® VpCI®-239 is free of CFCs and 1,1,1-Trichlorethane. Provides instant corrosion protection. In severely corrosive environments, ElectriCorr® VpCI®-239 can be used along with Cortec’s VpCI-100 series impregnated foam devices for extended continuous protection.

Advantages

• Excellent outdoor protection • Can be applied indoors • Fast-drying, nonsticky corrosion inhibiting film • Instant corrosion protection • Long-term protection • Minimized field service • Increased corrosion protection at a lower cost than conventional rust preventives • CFC and 1,1,1-Trichlorethane free • Vapor phase protection in vented or unvented enclosures • May be used as a cleaning agent • Moisture-displacing and penetrating film characteristics • Designed especially for protected outdoor electrical connections • Outdoor equivalent of VpCI-238 • UV dye additive can be seen once the carrier has evaporated

Applications

• Protects high or low voltage, and high or low current electrical and electronic devices such as relays,wiring, connectors, sensors • Printed circuit boards • Electrical contacts and components • Electric motors • Protects ferrous and non-ferrous metals • Used in contact with engineering plastics, elastomers, and other non-metallics • Outdoor generators and junction boxes • Outdoor and indoor electrical outlets

How to use

Spray a very light mist over the area needing protection. Dry time is approximately 1-2 hours at 700F and 50% relative humidity. VpCI®-239 application guide

Package: 1. 9.45 oz. aerosol spray (6 cans per carton)

Contact Us for other sizes and ordering.

Electricorr® VpCI®-238

Electricorr® VpCI®-238

Electricorr® VpCI®-238

Product Description

ElectriCorr® VpCI®-238 is an electronic cleaner containing Vapor phase Corrosion Inhibitor (VpCI). This cleaner is specifically formulated for electrical/electronic equipment, and components. ElectriCorr® VpCI®-238 forms a thin film of Vapor phase Corrosion Inhibitors effective against aggressive environments including industrial, marine, and tropical climates. This film does not alter the electrical resistance or magnetic properties of metal substrates. ElectriCorr® VpCI®-238 can be safely applied to protect circuits or relays without causing any changes in conductivity. It can be safely used with most plastics, elastomers, and other nonmetallics. ElectriCorr® VpCI®-238 is an effective inhibitor of galvanic corrosion for most metals and alloys normally found in electronics applications, such as aluminum, copper, ferrous, and other non-ferrous metals. ElectriCorr® VpCI®-238 is free of CFCs and 1,1,1-Trichlorethane. Application provides instant corrosion protection. In cases where severe corrosion may occur, ElectriCorr® VpCI®-238 can be used along with VpCI-100 series impregnated foam devices for extended protection.

Advantages

• Instant corrosion protection • Long-term multi-metal protection • Minimized field service • Increased corrosion protection at a lower cost than conventional rust preventatives • CFC- and 1,1,1-Trichlorethane-free • Vapor phase protection in vented or unvented enclosures • May be used as a cleaning agent

Applications

• Printed circuit boards • Electrical contacts and components • Electric motors • Corrosion protection of different metals in humid environment • Generators and junction boxes • Spray for use after final assembly or in the field

Independent Testing

ElectriCorr® VpCI®-238 has been tested by a world-renowned laboratory under accelerated conditions per the Batelle Flowing Mixed Gas Test in a Class III environment. The results showed excellent multi-metal protection equivalent to a 7-years protection interval in an indoor electronics environment

How to use

Dip part to be cleaned in VpCI®-238 or spray with ElectriCorr® VpCI®-238. Remove excess by drip, wipe, or other conventional method. Dry time approximately 1-2 hours at 700F and 50% relative humidity. Forced air is not recommended due to possible condensate and/or compressor oil contamination.Application is effective for 6+ months with proper controls.

Package: 1. 9.45 oz. aerosol spray (6 cans per carton)

Consumer Version 92381

Contact Us for other sizes and ordering.

Bullfrog 92381

Electricorr® VpCI®-238

Bullfrog 92381

Product Description

Bull Frog Electronic Cleaner (92381) removes the dirt, grit and corrosion that is silently attacking the performance and reliability of every electronic device, every electrical system that you own! Preferred by the U.S. Navy and repair technicians around the world

Applications

• Electrical connections • cars • trailers • equipment • outdoor lights • phones • remotes • TVs • VCRs • power tools • even light bulbs

How to use

Simply disconnect power and spray lightly on the surface to be cleaned. Remove rust and corrosion with a soft brush, cotton swab or soft cloth. Repeat if necessary. Wait until surface is dry to the touch before reconnecting power.

Industrial Size ElectriCorr® VpCI®-238

Buy Now for Bullfrog 92381 retail locations.

Contact Us for other sizes and ordering.