Packaging, Shipping and Storage with corrosion inhibitors

Cortec VpCI® Packaging, Shipping and Storage

Product Description

Cortec® offers a full range of VpCI® Packaging Solutions, some conform to international, government, military, and corporate specifications. VpCI® Packaging Solutions offer cost effective, high performance protection of parts, equipment, and structures for short or long-term, in environments from in-plant preservation to aggressive marine environments.

VpCI® Packaging Solutions range from coated papers, impregnated foams, extruded films, cushions, emitter devices, inserts, and custom designed solutions; ensuring ease of integration, simplicity of use, and uncompromised performance.

Cortec® is a world leader in biodegradable and compostable films. Cortec’s technological breakthrough of fully biodegradable films are designed to help businesses and governments to comply with stringent environmental guidelines. Cortec’s patented VpCI® technology; it is ideal for packaging applications where metal corrosion protection is crucial.Contact Us for details on biodegradable and compostable films.

Contact Us for industrial sales and other inquires.

VPCI BLUE FILM AND BAGS

Cor-Pak® VpCI® Stretch Film

Product Description

Cor-Pak® VpCI® Stretch Film is the ultimate high performance film, developed for corrosion protection of ferrous and non-ferrous metals. This film is coextruded using state-of-the-art resins, which offers superior strength and stretch characteristics as well as multimetal corrosion inhibiting properties that only VpCI® technology can deliver. Cor-Pak® VpCI® Stretch Film delivers puncture resistance and load holding, which allows a user to down-gauge,

contain aggressive loads, and produce a better package at reduced cost.

The combination of enhanced polyethylene resins with VpCI technology makes Cor-Pak® VpCI® Stretch Film the most advanced corrosion inhibiting stretch film available today on the market.

Advantages

• Does not contain polyisobutylene (PIB) or other tackifiers in cling layer, allowing discarded stretch film to be recycled • Does not leave residue on parts • Provides multimetal corrosion protection with VpCI® action • Protected parts can be used immediately without cleaning or degreasing • More economical and secure than tape, twine, or strapping • Holds protected parts securely in place • Self-adhering film bonds to each layer for added strength • Helps keep dust, dirt, and moisture off warehouse stock • Superior performance in light gauges allows downgauging and cost effectiveness •

Can be applied with standard equipment • Excellent clarity and cling • Up to a 3:1 stretch ratio • FDA approved for use on food handling equipment • Recyclable, environmentally friendly

Application Methods

Cor-Pak® VpCI® Stretch Film is compatible with commercially available manual and automatic stretch wrapping equipment.

Packaging

Available in standard hand wrap 12", 15" or 18" x 1500' roll (1mil/100 gauge) 4/carton; Machine grade film 20" x 4500' (1 mil/150 gauge)

Contact Us for Sample of Stretch film

VpCI®-126 Blue Bags

Product Description

(Rusted can - bag not sealed!)

VpCI®-126 bags Vapor phase Corrosion Inhibitor (VpCI®) 126 Series film combines the latest film technology with the most effective corrosion protection for all of your metal products. Sealing your product in Cortec® VpCI® films protects metal parts from all types of corrosion including rust, tarnish, stains, white rust, and oxidation for up to 5 years.* It’s as easy as putting your product in a Cortec® VpCI® package! *Depending on film construction thickness and application. Cortec® VpCI® films and bags replace conventional rust preventatives such as oils and desiccants. You save even more because VpCI® packaging eliminates the degreasing or coating removal required in the past. Now your product can be used immediately. VpCI®-126 is transparent, making it easy to identify parts. Additionally, it does not contain free amines, phosphates and is non-toxic and recyclable. VpCI®-126 bags protect metal objects as small as a needle to as large as the contents of an oceangoing container.

High Level of Corrosion Protection Metal parts packaged in Cortec® VpCI®-126 Blue receive continuous protection against salt, excessive humidity, condensation, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. The VpCI® vaporize and then condense to metal surfaces in the enclosed package. VpCI® reaches every area of your part, protecting its exterior as well as hard-to-reach interior surfaces. You get complete product protection during storage as well as during domestic and overseas shipments, virtually eliminating any rust claims. VpCI®-126 Series best selling anticorrosion PE film in world today with the highest level of corrosion protection demonstrated by standard corrosion test methods. Cortec® VpCI®-126, when used as intended, is compliant with Food and Drug Administration(FDA) regulations for packaging of food containers and food handling equipment. In addition, Cortec® VpCI®-126 Blue has received approval from leading institute regarding the recycling and disposal of packaging materials containing. Bottom line: VpCI®-126® Blue Bags, Film and sleeves keep everything corrosion free!

Contact Us for sizes and minimum quantities to order.

VpCI®-126 Blue

VpCI®-126 Blue

Product Description

VpCI®-126 Series Vapor phase Corrosion Inhibiting film combines the latest film technology with the most effective corrosion protection for all of your metal products. Sealing your product in Cortec® VpCI® films protects metal parts from all types of corrosion including rust, tarnish, stains, white rust, and oxidation for up to 5 years.* It’s as easy as putting your product in a Cortec® VpCI® package! Cortec® VpCI® films and bags replace conventional rust preventatives such as oils and desiccants. You save even more because VpCI® packaging eliminates the degreasing or coating removal required in the past and you can use your equipment immediately. VpCI®-126 is transparent, making it easy to identify parts. Additionally, it does not contain free amines, phosphates and is non-toxic and recyclable. VpCI®-126 Series films - bags protect metal objects as small as a needle to as large as the contents of an oceangoing container.

High Level of Corrosion Protection Metal parts packaged in Cortec® VpCI®-126 Blue receive continuous protection against salt, excessive humidity, condensation, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. The VpCIs vaporize and then condense to metal surfaces in the enclosed package. VpCI® reaches every area of your part, protecting its exterior as well as hard-to-reach interior surfaces. You get complete product protection during storage as well as during domestic and overseas shipments, virtually eliminating any rust claims. VpCI®-126 Series is the best selling anticorrosion PE film in the world today, with the highest level of corrosion protection demonstrated by standard and internal corrosion test methods. VpCI®-126 Blue film is typically made with 20% recycled content further improving the environmental footprint. DIY Video - See how to do

Sizes and Constructions

The material is available in a variety of standard and customized forms including bags, sheeting-reinforced film, Zip-Lock and Auto-Bags, gusseted liners, bags-on-a-roll, perforated sheeting, coil covers, shrink film, and tubing to protect small or large parts.

Contact Us for sizes and minimum quantities to order.

Cortec Shrinkfilm

VpCI®-126 Shrink Film

Product Description

Cortec VpCI-126 Shrink Film combines the latest film technology with the most effective corrosion protection for all of your metal products. Metal parts packaged in VpCI-126 Shrink Film receive continuous protection against salt, excessive humidity, condensation, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. Sealing your product in VpCI Shrink Film will protect a wide variety of metals from rust, tarnish, stains, white rust, and oxidation for up to 5 years.* It’s as easy as putting your product in VpCI Shrink Film! (*Depending on film construction thickness and application) VpCI-126 Shrink Film can replace conventional rust preventatives such as oils and desiccants. You save even more because VpCI-126 Shrink Film will eliminate all the degreasing or coating removal required in the past. Your product can now be used immediately. VpCI-126 is transparent, making it easy to identify parts. Additionally, it does not contain free amines, phosphates, or halogen-based materials and is non-toxic and recyclable.

Advantages

• Multimetal corrosion inhibition providing contact, barrier, and vapor phase protection • Produced with industrial grade LDPE for superior mechanical properties • Excellent sealing properties using sealing temperatures of 190- 240◦F • Will shrink up to 80% of original size using a wide variety of shrink tools • Transparent, allowing easy visualization • Film is recyclable and non-hazardous

High Level of Corrosion Protection

The Vapor phase Corrosion Inhibitors (VpCI®s) vaporize and condense on all metal surfaces in the Cortec VpCI®-126 Shrink Film. VpCI®s reaches every area of your part, protecting its exterior as well as hard-to-reach interior surfaces. Complete product protection during storage as well as during domestic and overseas shipments virtually eliminating any rust claims.

Metals Protected • Aluminum • Galvanized Steel • Carbon Steels • Stainless Steel • Silver • Copper • Solder • Brass

Sizes: standard size at 20’ x 100’ x 6 mil rolls.

Contact Us for other sizes and constructions.

Milcorr® VpCI® Shrink Film

Product Description

MilCorr® VpCI® Shrink Film is a heavy duty film featuring Cortec multimetal Vapor phase Corrosion Inhibitors. MilCorr® VpCI® Shrink Film provides a top-notch universal protection system with high ultraviolet (UV) light protection to maintain the integrity of the film itself as well as the parts packaged within. MilCorr® VpCI® Shrink Film, in conjunction with other Cortec® products, provides a total turnkey preservation for long term outdoor storage. MilCorr® VpCI® Shrink Film can replace conventional rust preventatives such as oils and desiccants. Parts protected with MilCorr® are ready to use with no additional cleaning and/or degreasing necessary, saving you time and money. Metal parts packaged in MilCorr® receive continuous protection against salt air and humid environments, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. The corrosion inhibitors vaporize and condense on all metal surfaces within the enclosed space, and diffuse to every area of your part; protecting its exterior as well as void spaces and recessed areas. You get complete product storage protection as well as during domestic and overseas shipments, virtually eliminating any rust claims.

Advantages

• Provides UV protection for outdoor storage • Multimetal corrosion inhibition providing contact, barrier and vapor phase protection • Superior mechanical properties • Will shrink using a wide variety of shrink tools including electric and propane heat guns • Provides a unitized, tight, and tamper-proof load • Extra protection for outdoor storage and export shipments • Effective in severe outdoor climates • Immediate use of protected object upon removal • Recyclable and non-toxic

Metals Protected • Steel • Solder • Iron • Aluminum • Brass • Copper • Nickel

Applications • Military vehicles and equipment preservation • Mothball preservation of industrial equipment • Export packaging of expensive larger equipment • Heavy equipment covers

Sizes: standard size of 20’ x 210’ x 10 mil

Contact Us for other sizes and constructions.

Cortec Emitters And Foams

VpCI®-101 Devices

VpCI®-105 Devices

VpCI®-105 Devices

Product Description

Cortec® impregnated foams and emitters protect precision machined parts and highly sensitive electronic components. They protect against breakage, surface damage, or scratches. VpCI®-101 devices are designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or tool boxes. A VpCI®-101 device protects up to 1 cubic foot (28 liters) in volume. VpCI®-101 is a small patented device from which Vapor phase Corrosion Inhibitors are slowly released. The corrosion inhibitors emit vapors that form a molecular layer on metal surfaces to protect critical, complex, and expensive electronic equipment and other metal components during operations, shipping, or storage. VpCI®-101 provides longterm protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others.

Advantages

• Economical to use • Quick and easy installation, compact and space-saving • Provides continuous protection up to 24 months during operation and/or shutdown • Effective in polluted and humid environments • Does not interfere with electrical, optical, or mechanical performance • Multimetal protection • Non-toxic and safe to handle • Free of nitrites, silicones, and phosphates • No spraying, wiping, or dipping required • Self-stick back, Self-stick date label

Typical Applications

• Operating, packaged, and stored electrical equipment • Marine navigation and communication equipment • Aerospace electrical controls • Electric motors • Switching equipment • Fuse boxes and power boxes • Medical equipment • Electrical wireways and terminal boxes • Control panels for manufacturing and processing equipment • Scientific and measuring instruments • Hand-held battery-operated devices • Telecommunications equipment and remote electronic devices • Tool boxes, parts storage, and other containers holding metals

How to Use

VpCI®-101 devices are extremely simple and convenient to install. The devices should be installed at the earliest possible time, preferably during manufacturing or assembly. Simply select a space within any enclosure where corrosion protection would be useful. Verify the surface where the device will be affixed is clean and free of debris. Peel off the protective peel strip from the bottom of the device and attach it to the clean surface. VpCI®-101 devices can be installed in any position. For volumes greater than 1 cubic foot (28 liters) use more than one device or VpCI-105 or VpCI-111. If the enclosure is not totally airtight, or if the access doors are opened frequently, replace the VpCI®-101 device more often than every 2 years. For additional protection, spray the enclosure very lightly with Cortec® ElectriCorr® VpCI®- 238 or VpCI®-239.

Protection: 1.0 ft3

Package: 50/carton.

Contact Us for other sizes and ordering.

VpCI®-105 Devices

VpCI®-105 Devices

VpCI®-105 Devices

Product description

Cortec® VpCI®-105 emitters are unique devices designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets, or tool boxes up to 5 cubic feet (141.6liters). The VpCI®-105 device emits Vapor phase Corrosion Inhibitors, which form a protective coating on all metal surfaces. VpCI®-105 is a patented plastic 2.3" diameter x 0.75" H emitter with a breathable Tyvek®* membrane through which the corrosion inhibitor is released. It provides long-term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others. Cortec® impregnated emitters protect precision machined parts and highly sensitive electronic components and protect against breakage, surface damage, or scratches. * Tyvek® is a registered trademark of Dupont®

Advantages

• Economical to use • Provides continuous protection for up to 24 months • Effective in polluted and humid environments • Does not interfere with electrical, optical, or mechanical surface properties • Multimetal protection • Quick and easy installation, safe to handle • Protects during operation and shutdown• Compact, space-saving, and unobtrusive device • Free of nitrites, halogens, and phosphates • No spraying, wiping, or dipping required • Self-stick back with self-stick date label • Accepted by FDA for corrosion protection of electrical and electronic equipment within food processing plants • Approved for U.S. military

Typical Applications

• Operating, packaged and stored electrical equipment • Marine navigation and communication electronic equipment • Electric motors • Switching equipment • Fuse boxes and power boxes • Medical equipment • Electrical wireways and terminal boxes • Scientific and measuring instruments • Telecommunications equipment • Remote electronics devices • Hand-held battery-operated devices • Control panels for manufacturing and processing equipment • Tool-boxes, gun safes, and enclosure for metal storage

How to Use

VpCI®-105 is extremely simple and convenient to install. The device should be installed at the earliest possible time. Simply select a space within any enclosure where corrosion protection would be useful. Verify the surface the device will be affixed to is clean and free of debris. Peel off the protective peel strip from the bottom of the device and attach it to the clean surface. VpCI®-105 emitters can be installed in any position. For volumes greater than 5 cubic feet (141.6 liters), use more than one device. If the enclosure is not totally airtight, or if the access doors are opened frequently, replace the VpCI®-105 device more often than every 2 years. For additional protection, spray the enclosure very lightly with ElectriCorr® VpCI®-238 or VpCI®-239.

Protection: 5.0 ft3

Package: 20/carton.

Contact Us for other sizes and ordering.

VpCI®-111 Devices

91321 Consumer Version of VpCI®-130 Series

91321 Consumer Version of VpCI®-130 Series

Product description

VpCI®-111 emitters are unique devices designed to provide corrosion protection for metal components and parts enclosed in non-ventilated control boxes, cabinets or tool boxes up to 11 cubic feet (312 liters). Cortec® emitters protect precision machined parts and highly sensitive electronic components. They protect against breakage, surface damage, or scratches. The Vapor phase Corrosion Inhibitor (VpCI®) emits vapors, which form a molecular layer on internal metal surfaces to protect critical, complex, and expensive electronic equipment during operation, shipping, or storage.

Cortec VpCI®-111 is patented plastic 2.3" diameter x 1.27" H emitter with breathable Tyvek® membrane cover through which corrosion inhibitors are slowly released. VpCI®-111 provides long term protection against corrosion even in the presence of adverse conditions including salt, moisture, airborne contaminants, H2S, SO2, NH3, and others. *Tyvek is a registered trademark of DuPontTM

Advantages

• Economical to use • Provides continuous protection for up to 24 months during operation and/or shutdown • Effective in polluted and humid environments • Does not interfere with electrical, optical, or mechanical performance • Multimetal protection • Quick and easy installation, compact and space-saving • Non-toxic and safe to handle • Free of nitrites, halogens, and phosphates • No spraying, wiping, or dipping required • Self-stick back and self-stick date label • Accepted by FDA for corrosion protection of electrical and electronic equipment within food processing plants •Approved for U.S. military, NATO and IBM

Typical Applications

• Operating, packaged, and stored electrical equipment • Marine navigation and communication equipment • Electric motors • Switching equipment • Fuse boxes and power boxes • Medical equipment • Electrical wireways and terminal boxes • Scientific and measuring instruments • Aerospace electrical controls • Telecommunications equipment and remote electronics devices • Control panels for manufacturing and processing equipment • Tool-boxes, gun safes, and any other enclosure for metal storage

How to Use

VpCI®-111 is extremely simple and convenient to install and should be installed as early as possible, preferably during manufacturing or assembly. Simply select a space within enclosed device where corrosion protection would be useful. Verify that the surface on which the device will be installed is clean and free of debris. Peel off the protective peel strip from the bottom of the device and attach it to the clean surface. The peel strip can be separated to reveal a self-adhesive sticker on which the installation and replacement dates can be noted. VpCI®-111 emitters can be installed in any position. For volumes greater than 11ft3 (312 L), install more than one VpCI®-111. If the enclosure is not totally air-tight or if the access doors are opened frequently, replace the VpCI®-111 emitter more often than every two years. After periods of heavy maintenance, replace the emitter. For additional protection, spray the enclosure very lightly with ElectriCorr® VpCI®-238 or VpCI®-239.

Protection:11.0 ft3

Package:10/carton.

Contact Us for other sizes and ordering.

91321 Consumer Version of VpCI®-130 Series

91321 Consumer Version of VpCI®-130 Series

91321 Consumer Version of VpCI®-130 Series

Product Description

Bullfrog Rust Blocker Shield (91321) - Stick it up in a Second...Stop Rust for a Year! Cortec® impregnated foams protect precision machined parts and highly sensitive electronic components. They protect against breakage, surface damage, or scratches. Stop rust for a year in any enclosed space up to 50 cubic feet with the invisible molecular protection of VpCI’s (Vapor Phase Corrosion Inhibitors). Ideal for any metal stored in an enclosed area. Used by the worlds largest companies to protect their critical assets from rust and corrosion.

Advantages

• Works better than conventional rust inhibitors, yet is Environmentally and User Safe • No nitrates, silicones, phosphates, heavy metals or other harmful chemicals • Won’t harm plastics, elastomers or painted surfaces • Works even under extreme conditions • Each shield will protect up to 50 cubic feet of space for 1 year

Typical Applications

• Storage lockers • Gun Safes • Large tool chests • Boat storage holds • Truck storage boxes • Pianos • Electrical Cabinets • Any thousands of other uses

How to Use

Simply remove foam 10-5/8" x 10-5/8"x 3/8" shield from plastic bag insert, put back into cardboard sleeve, write the date on back of box and insert into any enclosed space where there is metal for 1 year of corrosion protection. The VpCIs migrate from the foam to all metal surfaces within the enclosed space sealing out air and moisture that causes rust and corrosion.(Larger areas can be protected by combining multiple shields)

Protection: Each shield will protect up to 50 cubic feet

Package:12/carton.

Contact Us for other sizes and ordering.

Product Description

Cortec® VpCI®-130 Series Foams are unique flexible packaging materials that combine VpCI® protection, and desiccant action; plus excellent antistatic capabilities all in one step! You can now eliminate expensive and messy rust preventatives with VpCI®-130 Series Foams. Parts protected are always ready for use; no degreasing or coating removal is required. Metal parts packaged with VpCI®-130 Series Foams receive continuous protection against humidity, condensation, aggressive industrial atmospheres, dissimilar metal corrosion (galvanic corrosion), salt air, and residual impurities left after processing.

Advantages

Cortec® VpCI®-130 Series Foams are specially designed with Vapor phase Corrosion Inhibitor (VpCI®) impregnated throughout the foam’s polymeric matrix. They are excellent for protection of ferrous, non-ferrous metals, and alloys such as: steel, copper, brass, aluminum, zinc, solder, silver, etc. VpCI®-130 Series Foams do not change critical physical and/or chemical properties of electronic components, and are suitable for protection of printed circuit boards. VpCI®-130 Series Foams are nitrite- and chromate-free. The high performance patented formulation of VpCI® provides fast, easy-to-use protection even in aggressive overseas shipments. VpCI®-130 Series Foams contain approximately ten (10) times more VpCI® chemical per square foot (square meter) of substrate than the traditional VCI papers and other wrapping materials.

Cortec Desicorr® Pouches

Desicorr® VpCI® Pouches

Product Description

Desicorr® VpCI® Pouch is a specially designed two sided pouch which contains a unique combination of desiccant and VpCI® (Vapor phase Corrosion Inhibitor). Desicorr® VpCI® pouches are ideal for protecting packaged ferrous and non-ferrous metals from corrosion. Unlike conventional desiccants, the dual function of the Desicorr® VpCI® pouches reduces moisture in the air (desiccant action) and provides multimetal protection (VpCI® action) within a package. In essence, the desiccant action allows the VpCI® to have free access to the surface of the metal, without competition from moisture on the metal surface.

Advantages

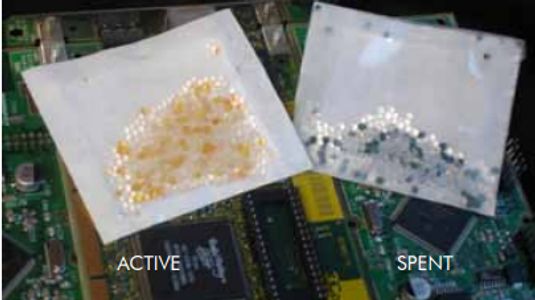

• Available in 1/6 and 1 Unit sizes • Synergistic action between desiccant and VpCI® gives unparalleled corrosion protection • VpCI continues to provide corrosion protection even when desiccant is fully spent • Color change from yellow to green, allows user to know when desiccant is fully spent • VpCI®action protects recessed and inaccessible surfaces • Protective VpCI® film does not need removal prior to using part • No degreasing or cleaning of protected part required

Multimetal protection • Aluminum • Carbon Steel • Stainless Steel • Copper • Brass • Galvanized Steel • Silicon Steel • Silver • Solder

Typical Applications

Desicorr® VpCI® is designed to protect products, components or assemblies when packaged in corrugated boxes, plastic wrap or bags, and wood or metal containers. •Motors •Completed assemblies, parts and components •Mechanical controls •Precision machined or stamped parts •Tools Marine and commercial electronic equipment • Electrical equipment

How to Use

Manually or automatically insert a Desicorr® VpCI® Pouch into the package. Then immediately close or seal container.

Protection: One Desicorr® VpCI® pouch is designed to protect 1 cubic foot. Desicorr® VpCI® Pouches will protect up to two years. Contains silica gel desiccant spheres and polyethylene VpCI® spheres.

Package: Desicorr® VpCI® Pouches 300/carton.

Contact us for ordering or further information

Desicorr® Pouches

Product Description

Desicorr® Pouches is a specially designed pouch to protect products from moisture damage. Whether in storage or in transit, products in nearly every industry require protection from moisture. Mildew, mold, rust, and an overall decrease in product efficacy are all common effects of moisture, costing millions in returned or unusable products each year. Desicorr® pouches help prevent damage by absorbing moisture.

Dessicorr® Pouches are available in both windowed and non-windowed versions (NW). The windowed version contains some indicator spheres that will change color from yellow to green when the desiccant is fully spent.

Advantages

Dessicorr®Pouches are available in 1/6, 1, and 2 Unit sizes. Dessicorr® pouches are constructed with breathable Dupont Tyvek on one side and clear film on the other, which allows visual confirmation when the desiccant is spent. Dessicorr® contains a desiccant with a color changing indicator: A yellow indicator that turns to green. This allows the user to know when the desiccant is spent and product should be replaced.

Typical Applications

Desicorr® Pouches are designed to protect goods within a sealed moisture barrier package or container from moisture damage. • Semiconductors • Electronics components • Circuit boards • Relays, communication devices • Museum storage • Optical devices • Military instruments • Machine parts

How to Use

Manually or automatically insert a Desicorr® pouch in the package. This number may vary depending on shipping conditions and the nature of the products being protected.

Protection: Desicorr pouches available in 1/6, 1, 2 Unit

Package: Desicorr® Pouches 300/carton. The shelf life of unopened cartons of Desicorr Pouches is up to 24 months. Desiccant spheres can be reused if heated until the yellow color reappears.

Contact Us for ordering.

VpCI Film Downloads

Videos

Cortec VpCI®-126 Film Wrap

Store metals Corrosion Free with Cortec VpCI®-126 VpCI 126 film

Cortec VpCI®-126 Shrink Film

Cortec's unique Vapor phase Corrosion Inhibitor technology has extensive use in all forms of packaging.

Packaging Video

Using Shrinkfast 998

Video

VpCI® Animation - How VpCI® work